KNITTING NEEDLES

In this article we will describe the main varieties of knitting needles, their specific features, size measurement systems, and choice of knitting needles for yarn of certain types and thickness.

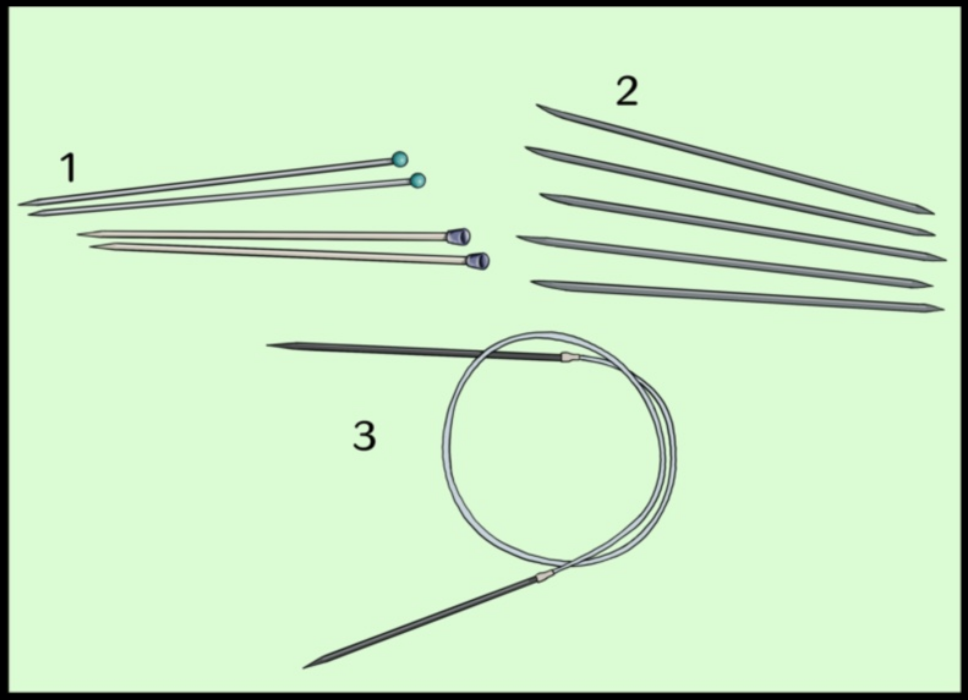

Knitting needles are tools whose working part is a long pin pointed at one end. The pointed tip is used to grab yarn while knitted stitches are placed on the pin. The other end of the needle is fitted with a knob (straight needles - fig.1) or connected with the second needle by means of a cable (circular needles - fig.3).

It should be reminded that two main techniques used in needle knitting are back-and-forth and circular knitting. Knitting needles may differ depending on the technique used.

Back-and-forth knitting: after all stitches in a row have been knitted, the work is turned to the other side (back) so that the last stitch of the previous row becomes the first stitch of the following row. The fabric has two (right and left) edges. Straight or circular needles are used for back-and-forth knitting.

Circular knitting: when the first row is knitted, it is closed into a circle (the first and the last stitches of the row are knitted together). Either needles connected to each other with a flexible cable or a set of 5 double-pointed needles can be used for circular knitting. All stitches are uniformly placed on four needles and closed into a circle while the fifth needle is used as a working one. The working needle constantly alters because new stitches are moved onto it while the emptied needle becomes the working one. Straight knitting needles cannot be used for circular knitting.

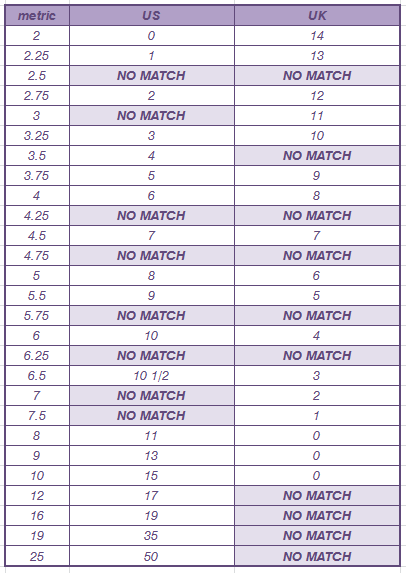

Knitting Needle Diameter Measurement Systems

It is crucial to know the diameter (thickness) of knitting needles because it is the right correlation between the knitting needle diameter and the yarn thickness that allows obtaining fabric of proper quality. Too thin needles used for thick yarn will provide non-elastic, rough fabric. It will be hard to knit because it will be difficult to pick stitches with the working needle and pull the yarn through them. At the same time, thick needles used for thin yarn will provide unsteady loose fabric. In this case, patterns can look very messy and stitches can slip off.

There are several needle measurement systems which originated in different countries: metric, English, American, Chinese and Japanese systems. Nowadays, measurements in the metric system and the system used in the manufacturer’s country are usually indicated on the package of knitting needles. The size of knitting needles is often specified on the tool as well. The size mark can be located on the knob (for straight needles) or on the pin or cable of circular needles. Below is a conversion table for different measurement systems:

If the package of your knitting needles has been lost and the size is not specified on the needles either, we recommend to use a special measuring device which can be purchased in a knitting store.

When yarn skeins are bought, the recommended size of knitting needles suitable for the yarn is always indicated on the label. This size normally corresponds to the stockinette stitch pattern. It should be noted that another needle size may be required for other patterns. Besides, each knitter has her own knitting manner which may also require a different size of needles.

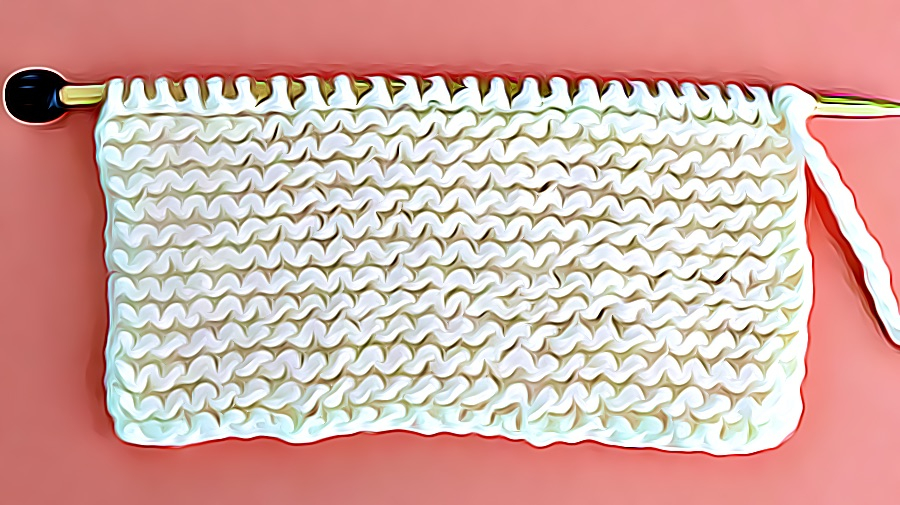

In any case, we strongly recommend you to make small swatches before you start knitting the main article in order to determine the most appropriate size of knitting needles. Start with knitting needles of the recommended size specified on the yarn label and replace them with smaller or bigger ones if required. You will see how the fabric will change and how the pattern will look. Moreover, the swatch will help you perform necessary calculations for the article. And when you wash the swatch, you will see how the yarn behaves after washing. More information about swatches is provided in the following articles on the website.

Yarn Types and Their Correlation with Knitting Needle Sizes

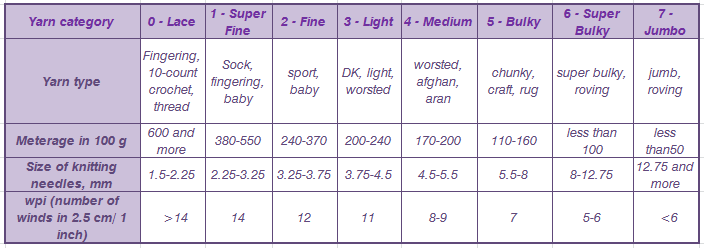

If there is no label on your yarn, use the table below to determine the suitable size of needles:

If you do not know the thickness of your yarn, you can determine it using the following method:

- Wind the yarn onto a ruler placing winds tight to each other but without overlapping

- Count the number of winds in 1 inch (2.5 cm)

- In the table above find the wpi value corresponding to the obtained number

- Determine the thickness of the yarn and the recommended size of knitting needles suitable for this kind of yarn

Materials Knitting Needles Are Made of

At present, knitting needles are made of various materials, both of natural and synthetic origin.

Here are the main materials used for making knitting needles:

- Wood. Knitting needles made of wood are light and feel nice in hands. But it should be remembered that they are usually rather fragile (particularly those of smaller diameters). Wood finishing should also be considered: the wood must be polished perfectly, without any roughness or scuffing. Some types of knitting needles are made of a few layers of wood (birch wood needles) and the tips of the needles can start delaminating after some time so that knitting will become unpleasant or even impossible.

- Bamboo. A cheaper analog of wooden knitting needles. For this type, finishing/polishing is also very important because bamboo is coarser than wood. When properly finished, bamboo knitting needles are not inferior to wooden ones.

- Aluminium with a special coating. It is a lightweight and inexpensive material. Its main disadvantage is its oxidation susceptibility if the coating is damaged. Besides, aluminium is rather soft and thin needles may be deformed by the weight of the fabric. Aluminium needles should not be used for light colored yarn because of its possible coloration.

- Stainless steel/ steel with a nickel coating. The most commonly used material. This kind of knitting needles allows the yarn to slide easily and the more they are used, the better polished by the yarn they become. Steel knitting needles are usually more expensive than those made of bamboo, aluminium or plastics. Their disadvantage is that they are heavier than other types. Some manufacturers fabricate knitting needles from common steel (for cheapening) and coat them with a special material protecting the needles from oxidation but the coating may wear off quickly, especially on the working tips of the needles.

- Plastic is a durable, lightweight and inexpensive material. Its disadvantages include worse sliding of yarn on the needles.

- Polycarbonate (carbon knitting needles). The material combines all advantages of its predecessors with almost no disadvantages. They are lightweight and durable and provide good sliding. Polycarbonate allows making knitting needles of any thickness, starting from 1 mm. The main drawback of the tool is its high price.

Each knitter can choose the knitting needles which suit her best. Preferences are individual. Some like using only wooden needles; some opt for only metal ones while others choose tools of different materials depending on the yarn. Many knitters believe that mohair yarn should be knitted with wooden/bamboo knitting needles while others do not think so. There is a rule: you won’t know if you don’t try.

Working Tips of Knitting Needles

The tip of the needle used to pick stitches and then the yarn can have different shapes:

- Pointed tip

- Rounded/ blunt tip

- Medium-sharp tip

The sharper the knitting needle tip, the easier it is to pick a stitch and pull the yarn through it but it should be noted that when working stitches off we use our finger, pressing the needle. If the tip of the knitting needle is too sharp and you are knitting tight, it can cause discomfort. When knitting loose twisted yarn consisting of several threads, the use of very sharp needles can result in splitting of the yarn which will slow down the knitting process significantly or can cause defects in the fabric.

Length of Pointed Parts of Knitting Needles

For the convenience of knitting and working stitches off, the pointed part of knitting needles is sometimes elongated. When using knitting needles of the kind, you should remember that this part of the needle is thinner and stitches formed on it can be smaller than those on the main part of the needles. This will hinder movement of stitches along the knitting needle and stitches themselves will have different size which will affect the look of the fabric.

Knitting Needle Section Shape

The most common shape of knitting needle section is round. However, square knitting needles are also becoming more and more popular. They are considered to provide smoother fabric without “lines”.

Lines are a fabric defect which arises when stockinette stitch pattern is knitted in back-and-forth rows. The defect is associated with the fact that knit and purl stitches forming the fabric have different height. Thus, on the fabric front we will see that one row is higher, the second one is lower, etc. As a rule, lines are typical for beginning knitters. Lines are most visible when low-elastic yarn is used. Lines may disappear or become less visible after washing of the fabric.

There are also knitting needles with triangular, pentangular or hexangular section. But they are less common and cannot be found in any store.

Connecting Cords/ Cables for Circular Knitting Needles

An essential element making a difference for convenience of knitting.

The cord should be elastic and yielding, without any creases or cracks. It is good if the cord rotates freely in the knitting needle socket. The transition from the cord to the needle must be as smooth as possible.

Cords can have different length which determines the overall length of circular knitting needles. The length of the cord matters when you are knitting in circle. To make knitting more comfortable, use the length of the cord which can hold all stitches of the piece tightly. Too long cord will cause the necessity to move stitches using special techniques which will slow down the knitting process.

If you are knitting in back-and-forth rows using circular knitting needles, choose the length of the cord so that all stitches of the fabric can be placed freely on the knitting needles and the cord.

Convertible Knitting Needles

For knitters’ convenience, detachable knitting needles are now available which allow changing the length of the connecting cord. The cord can be disconnected from the needles and replaced with another one with the required length. Cords and knitting needles are sold separately. You can buy cords of the necessary length and then get additional ones as required.

However, you should consider their connecting parts. There must not be any steps or burrs at the joint. Manufacturers offer different attachment systems for detachable knitting needles. All of them have their advantages and limitations. Therefore, it is advisable to test them in the store before purchasing, if possible. If it is impossible, read reviews of the product carefully and look at zoomed in photos of the knitting needles.

We have listed the main aspects you need to know when choosing new knitting needles. The range of available tools is quite wide and you are sure to find ones that will become your favorites.

Have a nice trip to the world of knitting