MACHINE KNITTING

In this article we will describe machine knitting technique in more detail and give you an idea of what to start your training with.

A knitting machine is a device for automation of the knitting process (creation of knitted fabric)

The first knitting machines appeared in the late 16th century. At the end of the 19th century, knitting machines were manufactured on an industrial scale. That was also when the first household knitting machines appeared which helped housewives speed up production of garments at home significantly.

In the 20th century, improvement of knitting machines continued, programmable knitting machines appeared, including those for household use, and the range of weaves (patterns) which could be performed widened.

Below are the main advantages and limitations of knitting machines.

Advantages:

- High knitting speed

- High quality of fabric

- Wide range of available patterns

- Automated performance of patterns by punch card and computerized machines

- For computerized machines and those fitted with template devices: sound notification of the need for changing the pattern, inputting additional yarn, increasing/decreasing of stitches, etc.

- Computerized machines allow automating creation of templates of articles in part or in full

Limitations:

- High price of the machine

- A large area is required for the machine installation

- Difficulty in eliminating possible fabric defects (dropped off stitches, dropped off fabric)

- Some operations can be carried out only manually (cast on, closing stitches, changing the number of stitches in a row, changing yarn, switching pattern types)

- Significant deformation of fabric when knitting. Beginning knitters may find it difficult to obtain the correct size of a garment.

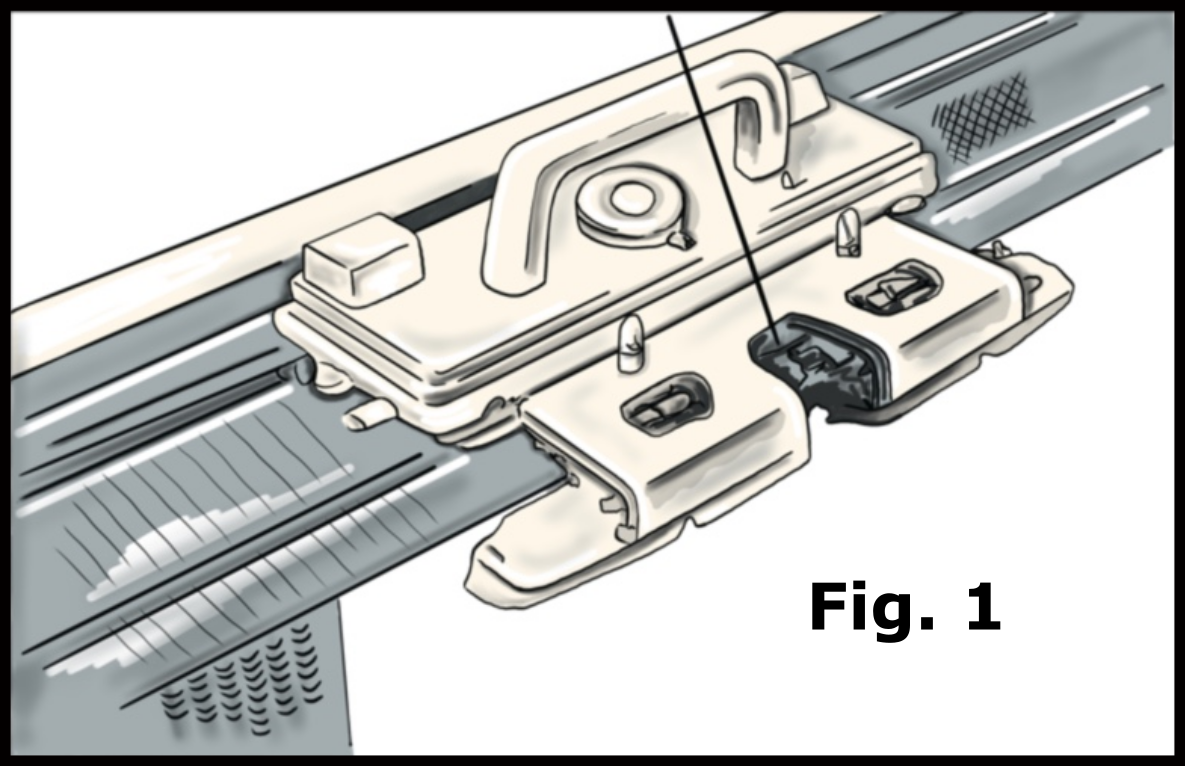

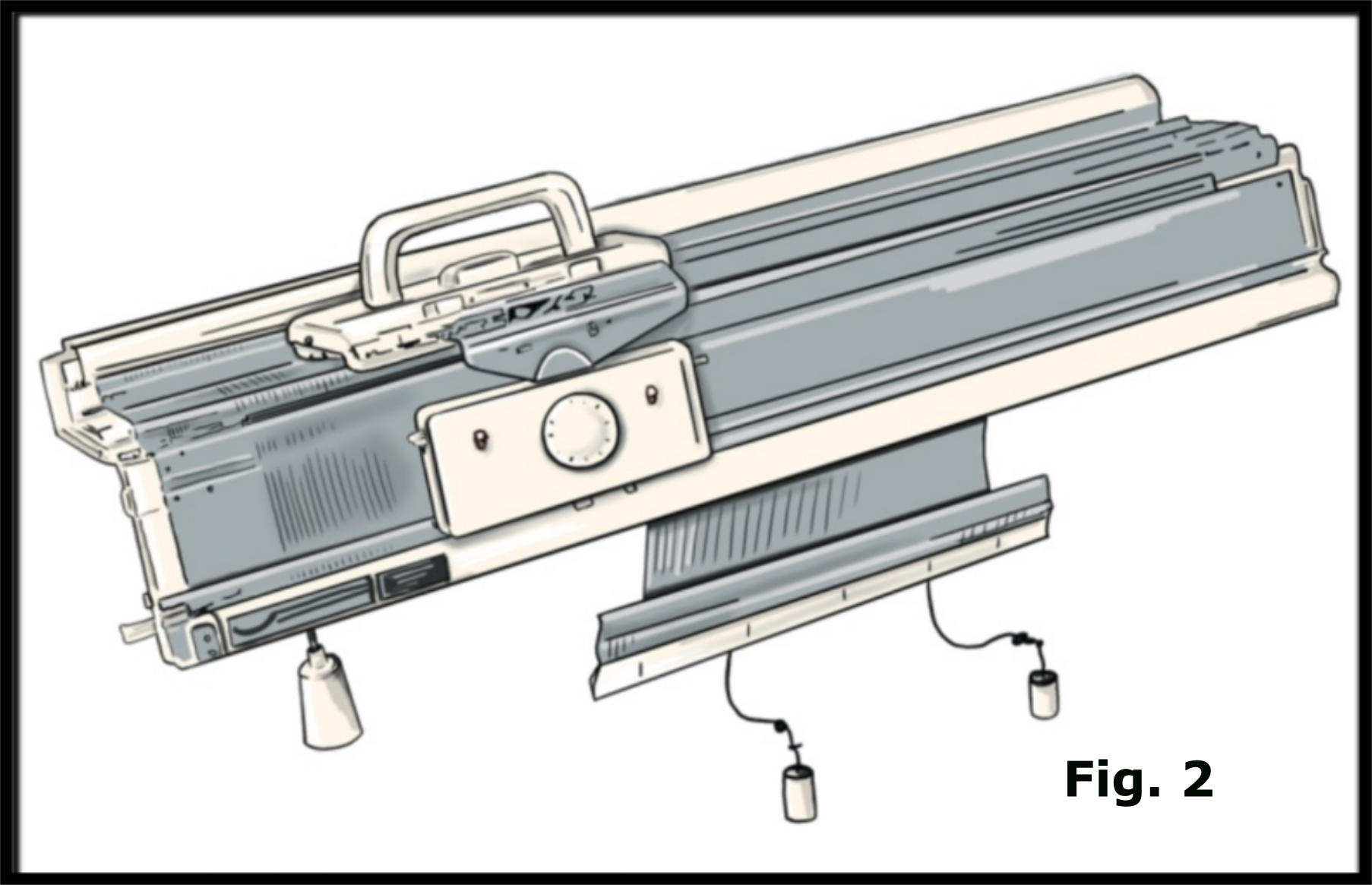

Nowadays, a household knitting machine is a desktop device which consists of needle bars, a carriage and a yarn tensioner.

A machine can have one or two needle bars. If there is one needle bar, the machine is called single needle bar machine. The needle bar is located horizontally and is referred to as the main/ rear needle bar. To perform a wider range of weaves (ribs, double knit Jacquard patterns, repp patterns) the second needle bar has to be used. Machines of this kind are called double needle bar machines. The second needle bar is located vertically and is attached to the main needle bar. The second needle bar is called auxiliary/ front needle bar.

Each needle bar holds needles. Yarn is passed through the needles by means of carriages. Carriages move to the right and to the left so that fabric is formed. The fabric is pulled down by a special bar and weights. Carriages allow controlling the vertical size of the stitch (knitting density) as well as selecting the pattern/ weave. The main carriage is supplied with the machine. It allows performing the main kinds of weaves: stockinette structure, fang patterns, Jacquard patters, etc. In order to make other types of weaves such as openwork, reverse stockinette stitch or intarsia, additional carriages have to be used which are not usually included in the main scope of supply.

Yarn tension is provided by a yarn tensioner. It supplies yarn from the bobbin steadily which is indispensible for obtaining fabric of proper quality.

Depending on the distance between the needles, household knitting machines can be divided into three classes:

- Class 3 machines – the distance between the needles is 9 mm – Bulky Guage

- Class 4 machines – the distance between the needles is 6.5 mm – Mid-Guage

- Class 5 machines – the distance between the needles is 4.5 mm – Standart Guage

The bigger the distance between the needles, the thicker yarn can be used for knitting and vice versa. Accordingly, fabric obtained with a class 3 machine is much thicker than that knitted by a class 5 machine. Below is the optimal yarn thickness for each class of machines:

- Class 3 – 100-200 m/100g

- Class 4 – 200-400 m/100g

- Class 5 – 300-800 m/100g

As has been stated above, each machine allows controlling the knitting density within a certain range. For this purpose, there is a special control on the main carriage graduated from 0 to 10. The smaller the value selected, the thinner yarn is required and vice versa.

The width of the needle bar is approximately the same for all machines and is about 1 m while the number of needles can vary:

- Class 3 – 110 needles

- Class 4 – 140 needles

- Class 5 – 200 needles

For many types of patterns, selection of needles is programmable: by means of a built-in punch card device or by software if the machine is computerized. The type of the pattern has to be selected manually on the main carriage using a special switch immediately before the pattern is to be performed.

The carriage is also moved on the needle bar manually by the knitter. There are special motors for automatic movement of fabric which have to be purchased separately.

Some other operations such as casting on the first row of stitches, increasing/ decreasing/closing stitches, extending/ narrowing the fabric or setting a relief also have to be carried out manually. Any defects that may occur during knitting such as dropped off stitches also have to be corrected manually.

Modern household knitting machines are rather reliable and will serve you for many years if operated correctly. There are mainly Chinese Silver Reed models of knitting machines available in the market now. They are reliable and take after models of Japanese and German manufacturers Toyota and Brother. You can also buy second hand knitting machines produced by European manufacturers.

What to Start with?

Machine knitting requires certain skills and takes more time than training in needle knitting or crochet.

Each knitting machine has a manual describing all the necessary operations from installation and maintenance of the knitting machine to assembly of articles.

After you have familiarized yourself with the instructions, you can start knitting your first articles.

There are numerous intramural machine knitting training courses of different duration. But the shops where training takes place are usually situated in big cities.

There are also some specialized online resources where you can study machine knitting. For example, KnitItNow.com.

There are a lot of video tutorials on Youtube.

It is essential to start learning machine knitting using appropriate yarn. The yarn has to correspond to your machine class in its thickness. Besides, the yarn has to have sufficient elasticity. It is better to start with half-wool yarn. Training should not be started with cotton, linen or silk yarn. Although these types of yarn can be used for machine knitting, they require certain skills: proper takedown of the fabric, particular tension of the yarn, etc.

It should also be remembered that yarn wound on special cones or reeled in bobbins by special coiling machines should be used for machine knitting. Yarn in skeins or hanks cannot be used for machine knitting because it will not be supplied uniformly which will result in fabric defects and in some cases even render knitting impossible.

To start with, we recommend you to knit small swatches using different yarn and different patterns/ weaves. Start working with a single needle bar and when you master this kind of knitting, proceed with knitting with double needle bars.

We recommend to start knitting from small articles consisting of few pieces and gradually proceed with bigger garments.

Have a nice trip to the world of knitting